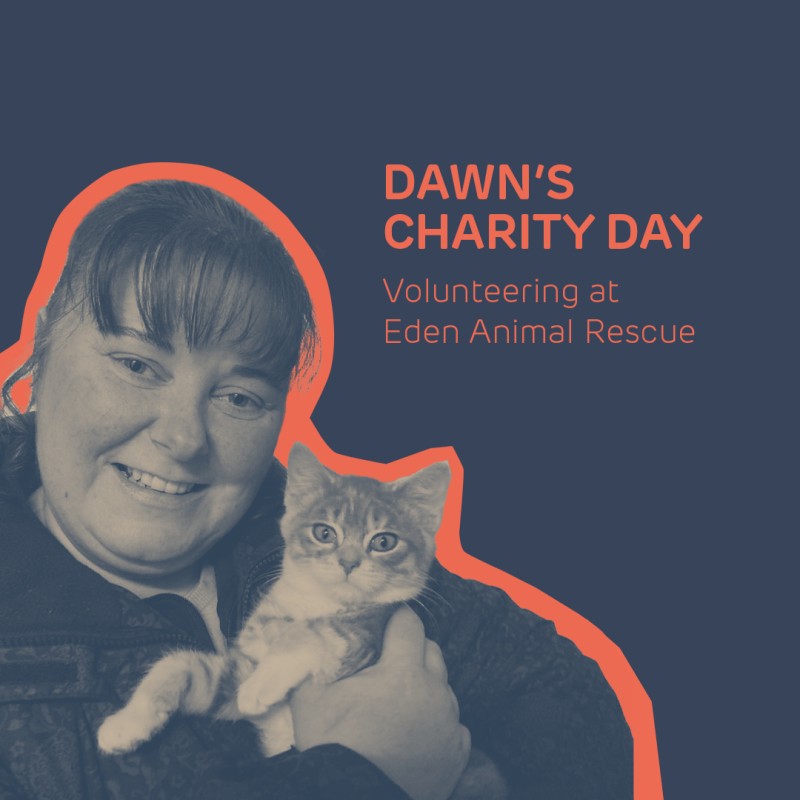

Dawn's Charity Day at Eden Animal Rescue

Dawn Woods, Print Finishing Assistant at our Print Facility in Penrith, recently took a Charity Day to volunteer at the Eden Animal Rescue Centre, spending her day caring for the cats at the shelter. ...

We are an integrated full service marketing agency focused on driving commercial growth and results through creative web design, digital marketing, printed products and bespoke signage.

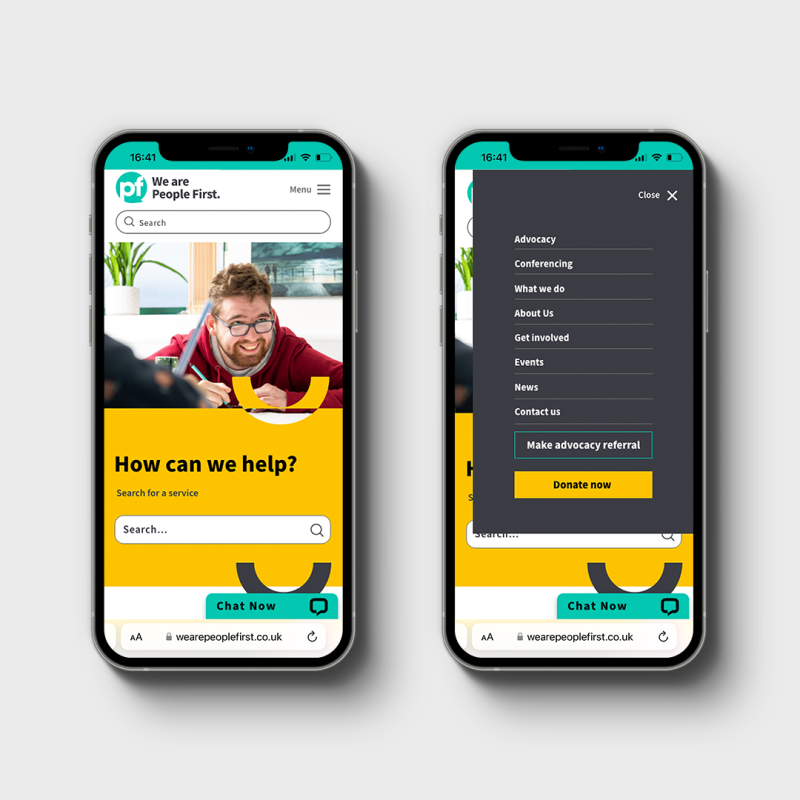

We design beautiful, user-friendly websites that work brilliantly for mobiles, desktops and tablets. Our experienced creative designers and developers have designed and built hundreds of websites for clients across many sectors. The website we create for you will help get you noticed and attract new inquiries.

Strategic, targeted design will make your business stand out from the crowd, reach the right markets and build trust with your customers. Our specialist team creates effective, memorable design solutions that build successful brands.

We build effective digital marketing strategies that are agile, impactful, and tailored to your business’ specific requirements. From captivating your audience with social media marketing, to placing your online presence on a pedestal with search engine optimisation or paid marketing, we’ll know exactly what approach to take to boost your success.

Printing is in our DNA. Our team has all the experience you need to help you reach your goals. Always moving forward, we invest in the latest technology to promote your business.

Your brand is much more than a name or a logo; it's the heart and soul of your business, it's what sets you apart from competitors. Let's delve into the importance of branding and explore the key steps to define your brand effectively. ...

Here at H&H Reeds, we are proud to work with many of the dedicated Breed Societies that safeguard the integrity and sustainability of the UK’s leading cattle and sheep breeds. As part of H&H Group, we collaborate closely with numerous businesses associated with the livestock sector in website design and digital marketing. ...